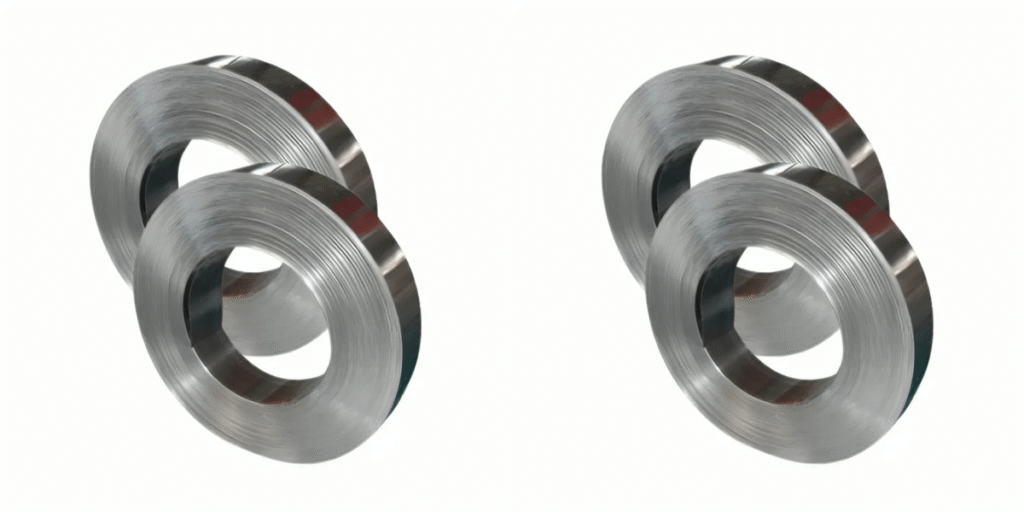

Stainless Strips Manufacturer

Table of Contents

Introduction

Welcome to Shree Vinayak Metals & Tube, a leading Manufacturer, Exporter, and Supplier of high-quality steel products based in Mumbai, Maharashtra. Since our establishment in 2010, we have been committed to providing exceptional products and services to our valued customers worldwide. At Shree Vinayak Metals & Tube, our mission is to deliver top-notch steel products that cater to diverse industries and applications. We strive to maintain the highest standards of quality, reliability, and customer satisfaction in all aspects of our business.

Certain materials play an underappreciated but crucial part in the complex dance of modern manufacturing, where durability, precision, and aesthetics collide. Stainless steel strips stand out among these; they are a strong, adaptable, and essential part that serves as the foundation for innumerable objects with which we come into contact on a daily basis. Stainless steel strips may be found everywhere, from the sparkling appliances in our kitchens to the delicate pieces in our cars, from life-saving medical gadgets to powerful industrial machinery, quietly adding to our world’s efficiency and longevity. We are the best Stainless Strips Supplier.

These sturdy machines, commonly known as FIBC (Flexible Intermediate Bulk Container) filling machines or big bag packing machines, are built for the precise and efficient filling of large bags—usually containing bulk solids weighing between 500 kg and 2000 kg. For any company aiming to broaden its market reach and export its goods, comprehending the significance of a dependable jumbo bag filling machine is crucial.

What Exactly is a Stainless Strips

Before we delve into the realm of manufacturing, let’s briefly grasp why stainless steel is considered a superstar material. Stainless steel, in contrast to regular steel that rusts easily, has a chromium content of at least 10.5%. This chromium interacts with atmospheric oxygen to create a thin, invisible passive layer on the surface. This layer serves as a protective barrier, blocking rust and corrosion, even when it is scratched. It is genuinely a wonder of self-healing. We are the best Stainless Strips Exporter.

Why Choose Shree Vinayak Metals & Tube

- Unyielding Quality Standards: Our operations are founded on quality. We use only the highest-quality raw materials and implement rigorous quality control at each step of production – starting with the initial melting and ending with slitting and packaging. Our stainless steel strips reliably fulfill or surpass national and international quality standards, guaranteeing that you receive a product that operates perfectly. We follow standards such as ASTM, DIN, JIS, among others.

- Cutting-Edge Production Facility: Our facility boasts advanced machinery and technology for precision slitting, edge conditioning, and finishing processes. Thanks to this, we can manufacture stainless steel strips that boast outstanding dimensional accuracy, uniform mechanical properties, and excellent surface finishes. This results in minimized waste and enhanced optimization of your production processes.

- A Broad Selection of Sizes and Grades: We recognize that varying applications necessitate different specifications. Shree Vinayak Metals & Tube provides a complete range of stainless steel grades, such as:

- Customization Capabilities: Every project is different, and so are its solutions. Our expertise lies in offering tailored stainless steel strips. Our skilled team can collaborate with you to produce strips that meet your precise requirements, whether you need specific dimensions, a certain surface finish (such as 2B, BA, HRAP, No.1, No.4, HL, etc.), specialized edge conditions (like slit edge, burr-free edge, rounded edge), or tight tolerances.

- Competitive Pricing: We ensure that our quality standards are met, but we also strive to provide our premium stainless steel strips at prices that are competitive. We can deliver affordable solutions that maintain performance thanks to our effective production methods and direct sourcing.

- On-time delivery: We recognize how crucial project deadlines are. With our efficient production planning and logistics, we guarantee timely processing and delivery of your stainless steel strip orders, thereby reducing your downtime and ensuring your projects stay on schedule.

- Experienced and Knowledgeable Team: Our team consists of highly skilled engineers, metallurgists, and production specialists with extensive expertise in stainless steel manufacturing. They are committed to delivering technical assistance, responding to your questions, and aiding you in choosing the perfect stainless steel strip solution for your needs.

- Customer-Centric Approach: Our customers lie at the core of all our actions at Shree Vinayak Metals & Tube. We are committed to establishing enduring relationships founded on mutual respect, trust, and transparency. We pay attention to your needs, offer tailored support, and aim to go beyond what you expect at each encounter.

- Commitment to Sustainability: We acknowledge our impact on the environment. We design our manufacturing processes to maximize efficiency and sustainability, and we advocate for the use of recyclable stainless steel.

Applications of Stainless Strips

- Automotive Industry: Stainless steel strips enhance the durability and safety of vehicles, from corrosion- and heat-resistant exhaust systems to trim, brackets, clamps, and parts in catalytic converters. Fuel efficiency is also becoming increasingly dependent on their strength-to-weight ratio.

- Kitchenware and Appliances: Take a look in your kitchen! Many internal and external parts of dishwashers, refrigerators, ovens, and washing machines are constructed from stainless steel strips. Consider the long-lasting, sanitary surfaces of sinks, countertops, and kitchen tools. It is crucial here to be able to withstand rust and to keep a neat appearance.

- Construction and Architecture: Decorative trims, fascias, window frames, roofing elements, and even structural reinforcements utilize stainless steel strips. Due to their aesthetic appeal, durability, and low maintenance requirements, they are favored for modern buildings, particularly in coastal or industrial areas where corrosion is a concern.

- Medical and Pharmaceutical: Certain stainless steel grades are ideal for surgical instruments, implants, hospital equipment, and pharmaceutical processing equipment due to their highly sterile and corrosion-resistant properties. Delicate parts of medical devices are made using precision-rolled strips.

- Electronics and Electrical Components: Stainless steel strips are used in connectors, battery casings, springs, shielding, and circuit board components. Their conductivity (in certain grades), resistance to corrosion, and capacity for precise formation are crucial.

- Consumer Goods: Stainless steel strips enhance durability, provide a premium feel, and resist everyday wear and tear in products ranging from watch cases and jewelry to cutlery, pens, and bicycle components.

- Industrial Equipment: In manufacturing and processing facilities, stainless steel strips are utilized for conveyor belts, filtration systems, valves, and other elements that must endure corrosive substances, elevated temperatures, or abrasive materials.

- Fasteners and Hardware: Stainless steel nuts, bolts, washers, clips, and springs made from strips provide enhanced corrosion resistance compared to other materials, making them suitable for outdoor applications or corrosive environments.

- Heating, Ventilation, and Air Conditioning (HVAC): Stainless steel strips are utilized in ductwork, heat exchangers, and various components because of their ability to resist condensation and corrosion, thus ensuring the long-term efficiency of the system.

Specifications Table of Stainless Strips

| Property | Available Range / Options |

|---|---|

| Product | Stainless Strips |

| Thickness | 0.15 mm to 2.00 mm+ (±0.005 mm accuracy) |

| Width | 5 mm to 200 mm+ (cut-to-width or slit) |

| Length | Coils (50–1,500 kg) or cut strips up to 6 meters |

| Edge Type | Mill edge, trimmed, deburred |

| Finish | 2B mill, BA (bright annealed), 2D (cold rolled matte), mirror, satin |

| Coiling Tension | Controlled to prevent coil set |

| Mechanical Strength | Tensile: 500–750 MPa; Yield: 200–480 MPa |

| Elongation | 20% – 60% (depending on the alloy & temper) |

| Surface Quality | No pits, scratches, oil stains; passivation available |

| Certifications | ISO 9001; ASTM A666 / A240; JIS G4303; EN10088; 3.1 / 3.2 certificates |

Types of Stainless Strips

1. Hot Rolled Stainless Strips

- Hot rolled stainless strips are manufactured by rolling stainless steel at high temperatures. They are known for their strength and durability, making them suitable for structural applications.

2. Cold Rolled Stainless Strips

- Cold rolled stainless strips are processed at room temperature. They have a smooth finish, precise dimensions, and high strength, which makes them ideal for applications requiring tight tolerances and an attractive appearance.

3. Precision Stainless Strips

- These are extremely thin and narrow stainless strips manufactured with high precision. They are used in industries where accuracy is crucial.

4. Slit Edge Stainless Strips

- These strips have edges produced through a slitting process. Slit edge stainless strips are cost-effective and commonly used in various fabrication applications.

5. Deburred Edge Stainless Strips

- Deburred edge strips have smooth edges that are free from sharp burrs or irregularities. This makes them safer to handle and reduces the risk of injury during processing.

Conclusion

Stainless steel strips are much more than merely a commodity; they are meticulously manufactured parts essential to the performance, longevity, and appearance of innumerable products around the globe. The strips’ quality has a direct effect on the end product’s performance and success, so selecting a manufacturer is a crucial choice. We are the best Best Stainless Strips Manufacturer.

We at Shree Vinayak Metals & Tube are very proud to be a prominent producer of stainless steel strips. We stand out in the industry due to our steadfast dedication to quality, precision, customization, and customer service. We recognize the vital part our products play in your success, and we are committed to supplying you with materials that go beyond your expectations.