Brass Pneumatic Fittings Manufacturer

Introduction

Welcome to Shree Vinayak Metals & Tube, a leading Manufacturer, Exporter, and Supplier of high-quality steel products based in Mumbai, Maharashtra. Since our establishment in 2010, we have been committed to providing exceptional products and services to our valued customers worldwide. At Shree Vinayak Metals & Tube, our mission is to deliver top-notch steel products that cater to diverse industries and applications. We strive to maintain the highest standards of quality, reliability, and customer satisfaction in all aspects of our business.

Compressed air is essential to practically every business you can think of, including manufacturing, automotive, medical, and even food processing. It drives innumerable operations, runs tools, and powers machines. However, that compressed air needs a dependable means of connection and transportation in order to function properly. Pneumatic fittings are useful in this situation, and brass pneumatic fittings are particularly notable for their performance and longevity.

Although you may not give these minor parts much thought, they are the unsung heroes of many operations, guaranteeing seamless, leak-free air line connections. Additionally, you should be aware of Shree Vinayak Metals & Tube if you’re searching for a manufacturer who provides excellent quality and recognizes the crucial necessity of these products. We are the best Brass Pneumatic Fittings Supplier.

What Exactly Are Brass Pneumatic Fittings

Let’s put it in plain language. The term “pneumatic” describes anything that uses compressed gas or air. “Fittings” are the connections used to link various system components. Therefore, brass pneumatic fittings are just brass connectors utilized in systems that include pressurized air. We are the best Brass Pneumatic Fittings Exporter.

Why Choose Shree Vinayak Metals & Tubes

- Uncompromising Quality: At Shree Vinayak Metals & Tubes, quality isn’t just a buzzword; it’s the cornerstone of everything we do. We utilize only the finest grades of brass, rigorously tested to ensure superior strength, corrosion resistance, and longevity. Our manufacturing processes adhere to stringent quality control standards, ensuring every fitting that leaves our facility is flawless and performs reliably under pressure.

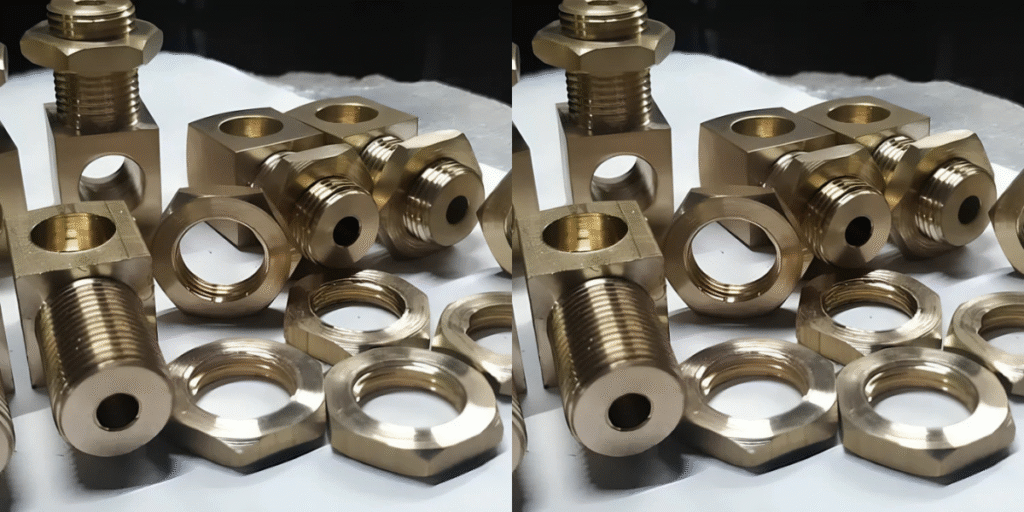

- Precision Engineering: We believe in the power of precision. Our state-of-the-art manufacturing facility and skilled engineers ensure that every brass pneumatic fitting is crafted with meticulous accuracy. This means perfect threading, precise dimensions, and optimal sealing capabilities, leading to efficient and leak-free pneumatic systems.

- Extensive Product Range: We understand that every application is unique. That’s why Shree Vinayak Metals & Tubes offers a comprehensive range of brass pneumatic fittings to cater to diverse industrial requirements. Whether you need standard push-to-connect fittings, specialized adaptors, or custom-designed solutions, our vast inventory and manufacturing capabilities ensure you’ll find exactly what you need.

- Commitment to Customer Satisfaction: Your success is our priority. Our knowledgeable and responsive customer service team is always ready to assist you, from helping you select the right fitting for your application to providing technical support. We believe in building long-term relationships based on trust and mutual success.

- Competitive Pricing: While we never compromise on quality, we also understand the importance of cost-effectiveness. Shree Vinayak Metals & Tubes offers highly competitive pricing without sacrificing the superior quality of our brass pneumatic fittings, providing you with exceptional value for your investment.

- Reliable Supply Chain: We recognize the importance of timely delivery in keeping your operations running smoothly. Our efficient production processes and robust supply chain ensure that your orders are processed and dispatched promptly, minimizing lead times and preventing costly delays.

- Ethical Business Practices and Strong Customer Relationships: We are committed to building enduring relationships with our customers based on trust, dependability, and outstanding service. Our client-centric approach, transparent dealings, and ethical business policies have helped us cultivate a vast and loyal customer base.

- Robust Supply Chain and Timely Delivery: With our established infrastructure and vast production capacity, we are better equipped to handle large orders and ensure timely delivery, minimizing delays in your projects. We have strong relationships with reliable raw material suppliers, guaranteeing consistent quality from the very beginning.

- Advanced production Skills: We have a cutting-edge production facility with the latest equipment and tools for precise welding, bending, and finishing. This enables us to manufacture brass pneumatic fittings that are essential to the effectiveness of your pneumatic systems because they have precise measurements, smooth inside surfaces, and leak-proof connections.

Applications of Brass Pneumatic Fittings

- Industrial Automation and Robotics: This is perhaps the most significant application. Brass fittings are critical in connecting cylinders, valves, sensors, and actuators in automated assembly lines, robotic arms, and pick-and-place systems. They ensure the precise and rapid movement required for modern manufacturing. Our fittings contribute to the smooth operation of packaging machinery, material handling systems, and automated welding equipment.

- Automotive Industry: From paint shops to assembly lines, pneumatic tools and systems are ubiquitous in automotive manufacturing. Brass fittings are used in air brake systems, engine testing equipment, and various pneumatic tools for assembly and repair.

- Textile Industry: Pneumatic systems power a multitude of textile machinery, including looms, spinning machines, and dyeing equipment. Our brass fittings ensure reliable air flow for controlling various functions and movements.

- Pharmaceutical and Food & Beverage: In these industries, hygiene and non-contaminating materials are paramount. While stainless steel is often preferred for contact parts, brass fittings are used in non-contact pneumatic control systems, especially where robustness and corrosion resistance are still needed in the surrounding environment. Our fittings help power packaging machines, filling lines, and sorting equipment.

- Medical Equipment: Many medical devices, from dental chairs to hospital beds, rely on pneumatic controls for adjustable functions. Precision brass fittings are vital for the reliable operation of these sensitive pieces of equipment.

- Packaging Machinery: Automated packaging lines heavily utilize pneumatic cylinders and valves for tasks like gripping, sealing, and moving products. Shree Vinayak Metals & Tube’s fittings ensure the rapid and precise movements required for high-speed packaging.

- Printing and Paper Industry: Pneumatic systems are used in printing presses for paper feeding, stacking, and ink control. Our brass fittings contribute to the smooth and uninterrupted operation of these complex machines.

- HVAC Systems: Heating, Ventilation, and Air Conditioning systems often incorporate pneumatic controls for dampers, valves, and actuators. Brass fittings provide durable and reliable connections in these critical environmental control systems.

- Agricultural Machinery: Modern agricultural equipment increasingly uses pneumatic systems for various functions, from seed planting to harvesting. Our robust brass fittings can withstand the demanding outdoor environments.

- Construction Equipment: Pneumatic tools and systems are common in construction, including air compressors, jackhammers, and concrete vibrators. Our fittings ensure durable connections for these heavy-duty applications.

- General Industry Applications: Beyond these specific sectors, brass pneumatic fittings from Shree Vinayak Metals & Tube are used in air compressors, industrial air tools, spray painting equipment, tire inflation systems, and countless other applications where controlled compressed air is essential.

Table of Specifications Brass Pneumatic Fittings

| Parameter | Specification |

|---|---|

| Material | Brass Pneumatic Fittings |

| Threads Available | BSP, NPT, Metric, UNF |

| Tube Sizes | 4mm to 16mm (Push Fit), 1/8” to 1” |

| Working Pressure | Up to 300 PSI |

| Temperature Range | -20°C to +120°C |

| Surface Finish | Natural Brass / Nickel Plated |

| Thread Tolerance | ISO 228 / DIN 3852 |

| Sealing Type | O-Ring / Teflon Tape |

| Connection Type | Push-in, Threaded, Compression |

| Standards | ROHS Compliant, ISO 9001:2015 Certified |

Benefits of Brass Pneumatic Fittings

- Corrosion Resistance: Brass is inherently resistant to corrosion, especially from moisture and various chemicals often present in industrial environments. This ensures a longer lifespan for the fittings and reduces the risk of system failures due to degradation.

- Durability and Strength: Brass is a robust material, capable of withstanding significant pressure and repeated use without deforming or cracking. This durability translates to less downtime and lower maintenance costs.

- Excellent Machinability: Brass is relatively easy to machine, allowing manufacturers to create complex and precise designs. This precision is crucial for ensuring tight seals and optimal performance.

- Good Thermal Conductivity: While not always the primary concern in pneumatic systems, brass’s ability to conduct heat can be beneficial in certain applications, helping to dissipate any heat generated within the system.

- Cost-Effectiveness: Compared to some other high-performance materials, brass offers an excellent balance of properties and cost, making it a very economical choice for a wide range of pneumatic applications.

- Versatility: Brass fittings come in a vast array of shapes and sizes – from straight connectors and elbows to tees, reducers, and quick-disconnect couplings. This versatility ensures that there’s a brass fitting for virtually every connection need.

- Longer System Lifespan: Our fittings help to prolong the life of costly equipment by preventing leaks and maintaining appropriate pressure, which lessens wear and tear on your entire pneumatic system.

Types of Brass Pneumatic Fittings

1. Brass Push-to-Connect Fittings

- Use: Quick installation and disconnection of tubes.

- Advantage: No tools required.

- Application: Ideal for air tubing in automation and robotics.

2. Brass Compression Fittings

- Use: Creates tight seals by compressing ferrules on the tubing.

- Advantage: Strong and leak-proof.

- Application: Common in air, gas, and fluid systems.

3. Brass Hose Barb Fittings

- Use: Connects flexible hoses to rigid tubing.

- Advantage: Secure grip and good airflow.

- Application: Used in low-pressure air lines.

4. Brass Male & Female Connectors

- Use: Connect two components with male-female threading.

- Advantage: Versatile and easy to use.

- Application: General purpose pneumatic connections.

5. Brass Elbow Fittings (90° and 45°)

- Use: Change the direction of airflow.

- Advantage: Reduces stress on tubes.

- Application: Compact systems where space is limited.

Conclusion

A wide range of contemporary machinery and industrial operations are made possible by the silent workhorses known as brass pneumatic fittings. They are the best option for any application needing dependable air pressure management because of their remarkable qualities, which include corrosion resistance, durability, excellent sealability, and machinability. We are the best Best Brass Pneumatic Fittings Manufacturer.

Selecting a reliable and skilled producer of brass pneumatic fittings is crucial for companies and sectors that cannot afford to sacrifice longevity and performance. In this field, Shree Vinayak Metals & Tube is a shining example of excellence. We are committed to offering the essential parts that enable your pneumatic systems to function faultlessly because of our everlasting dedication to quality, precision engineering, and customer satisfaction.