SS Syphon Tube Manufacturers in Mumbai

Table of Contents

Introduction

Welcome to Shree Vinayak Metals & Tube, a leading Manufacturer, Exporter, and Supplier of high-quality steel products based in Mumbai, Maharashtra. Since our establishment in 2010, we have been committed to providing exceptional products and services to our valued customers worldwide. At Shree Vinayak Metals & Tube, our mission is to deliver top-notch steel products that cater to diverse industries and applications. We strive to maintain the highest standards of quality, reliability, and customer satisfaction in all aspects of our business.

Mumbai, India’s financial capital and industrial powerhouse, buzzes with ceaseless activity from various industries. Whether in extensive petrochemical facilities, pharmaceutical production units, lively textile mills, or food processing establishments, the precise and safe assessment of fluid pressure is crucial. The SS Syphon Tube is a core element of this crucial operation, one that may appear unimportant at first glance but is in fact essential.

These specialized tubes, which are frequently disregarded, act as essential protectors for sensitive pressure gauges and transmitters, shielding them from the harmful consequences of elevated temperatures, fluctuating pressures, and corrosive substances. Mumbai is a city where industrial processes frequently involve extreme conditions, leading to a continual demand for trustworthy and high-quality SS Syphon Tube Manufacturers in Mumbai. We are the best SS Syphon Tube Supplier.

What is an SS Syphon Tube

A protective accessory known as an SS Syphon Tube is placed between a process line and a pressure measuring instrument (such as a pressure gauge, transmitter, or switch). Its main purpose is to establish a barrier usually a condensate seal—that stops hot process media from coming into direct contact with the delicate internal parts of the measuring instrument. Picture a steam line functioning at several hundred degrees Celsius. A pressure gauge connected directly would suffer damage from the high temperature, which would compromise its sensitive diaphragm or bourdon tube and result in erroneous measurements, instrument malfunction, and possibly hazardous circumstances. At this point, the syphon tube is used. We are the best SS Syphon Tube Exporter.

Why Choose Shree Vinayak Metals & Tube

- Unflinching Dedication to Quality: Our business is founded on quality. We source only top-grade stainless steel (SS304, SS316, SS316L, and other specialized alloys as needed) from reliable mills. We exercise careful control over our manufacturing processes, and each SS Syphon Tube is subjected to thorough testing—hydrostatic and pneumatic tests included to guarantee that it has no defects and will perform as expected in the conditions specified. Our systematic approach to quality management is evidenced by our status as an ISO-certified company.

- Advanced Manufacturing Capabilities: Our cutting-edge manufacturing facility located in Mumbai features modern tools and machinery for precision bending, welding, and finishing. Our talented engineers and technicians utilize their knowledge to manufacture SS Syphon Tubes that offer remarkable dimensional precision and structural soundness, guaranteeing peak performance and durability.

- IBR Approved (Indian Boiler Regulations) Syphons: In applications that involve steam and boilers, obtaining IBR approval is essential for compliance and safety. Upon request, Shree Vinayak Metals & Tube can supply IBR-approved SS Syphon Tubes, guaranteeing that your installations comply with all regulatory standards.

- Competitive Pricing and Timely Delivery: We always maintain quality standards, but we aim to provide our premium SS Syphon Tubes at prices that are competitive. Additionally, our effective production methods and strong supply chain allow us to guarantee punctual deliveries, thus reducing downtime for your operations in Mumbai and elsewhere.

- Expert Technical Support: Our group of seasoned experts has extensive expertise in SS Syphon Tube applications and material science. We offer extensive technical support, assisting you in choosing the most suitable syphon tube for your unique pressure and temperature conditions to guarantee maximum safety and measurement precision. We are not merely manufacturers; we are your technical allies.

- Robust Customer Relationships: Our focus at Shree Vinayak Metals & Tube is on establishing enduring relationships with our customers, founded on trust, dependability, and outstanding service. Our focus on customers guarantees that we respond to your needs, communicate transparently, and secure total satisfaction.

- Global Reach: Shree Vinayak Metals & Tube, while firmly established as a top SS Syphon Tube Manufacturer in Mumbai, also caters to a broad network of international clients. We export our products to multiple countries, showcasing our compliance with global quality standards and our ability to satisfy various international demands.

Applications of SS Syphon Tube

- Reliance Industries Jamnagar Refinery: Within these enormous refinery complexes, thousands of pressure gauges track the performance of different units such as crude distillation units, catalytic crackers, and hydrotreaters. SS Syphon Tubes, produced by manufacturers such as Shree Vinayak Metals & Tube under strict specifications, are essential for safeguarding these instruments from steam, hot hydrocarbons, and process acids, thus guaranteeing safe and continuous operations.

- Tata Power Plants: In a large-scale power plant, boiler units function under pressures of hundreds of bars and temperatures over 500°C. Our SS Syphon Tubes are essential for safeguarding the many pressure gauges linked to steam headers, superheaters, and re-heaters, which is vital for accurate control and avoiding disastrous failures.

- Pharmaceutical Giants: During the manufacturing of pharmaceuticals, especially in processes like sterilization, distillation, and formulation, high-purity steam and a range of chemical agents are utilized. The SS 316L syphon tubes from Shree Vinayak Metals & Tube are perfect for these uses, providing temperature protection and compliance with stringent hygiene standards to avert contamination of vital drug products.

- ONGC Offshore Platforms associated with Mumbai’s oil & gas sector: Although these platforms are not located within Mumbai, the city’s infrastructure is frequently used for overseeing and coordinating offshore oil and gas activities. SS Syphon Tubes on these platforms are subjected to corrosive saltwater, elevated pressures, and severe temperatures due to crude oil and natural gas streams. The safety and efficiency of these essential assets depend on the corrosion resistance and robustness of our SS Syphon Tubes.

- Large Food & Beverage Manufacturing Facilities: In facilities that produce dairy products, processed foods, or beverages, processes such as pasteurization, cooking, and steam-in-place (SIP) cleaning utilize high temperatures. Our food-grade SS Syphon Tubes guarantee precise and secure pressure monitoring during these crucial steps, while maintaining product quality and hygiene standards.

- Power Generation Thermal and Gas-based: Power plants utilize steam that is both high-pressure and high-temperature. SS syphon tubes are crucial for dependable pressure measurement in boilers, turbines, and steam lines, guaranteeing safe and efficient energy production.

- Pharmaceutical Industry: Mumbai serves as a key center for pharmaceuticals. It is essential to maintain strict hygiene and precision. Syphon tubes made of SS316 are often favored due to their cleanliness and ability to resist contamination, safeguarding instruments in critical process lines.

- Food and Beverage Processing: As with pharmaceuticals, this industry requires hygienic materials. SS syphon tubes provide precise pressure measurements during pasteurization, sterilization, and different fluid transfer operations, all while maintaining the quality of the product.

Table Specifications of SS Syphon Tubes

| Parameter | Details |

|---|---|

| Product | SS Syphon Tubes |

| Material Grades | SS 304, SS 304L, SS 316, SS 316L, SS 321 |

| Type | Pigtail Syphon, U-Type Syphon, Coil Syphon |

| Size Range | ¼” NB to 2” NB |

| Thickness | Sch 5S, 10S, 40S, 80S |

| End Connections | Threaded (NPT, BSP), Butt Weld, Socket Weld |

| Temperature Range | Upto 600°C |

| Pressure Rating | Upto 6000 PSI |

| Surface Finish | Polished, Pickled, Annealed |

| Standards | ASTM A312, ASTM A213, ASME B36.19, DIN, JIS, BS |

| Applications | Boilers, Steam Lines, Chemical Plants, Refineries, Power Plants |

Advantage of SS Syphon Tubes

- Material Quality of the Highest Standard: We use only high-quality stainless steel, including SS 304, SS 316, and SS 316L, obtained from reliable suppliers. This guarantees that our SS Syphon Tubes provide outstanding corrosion resistance, ability to withstand high temperatures, and durability, even in the harshest industrial settings. This constitutes the basic “Advantage Large”: a sturdy and trustworthy product from its very foundation.

- Precision Engineering and Manufacturing Excellence: Our production methods use advanced techniques and skilled craftsmanship. Every syphon tube is crafted with precision, welded (where necessary for specific types), and refined to guarantee exact measurements, smooth internal surfaces, and connections that do not leak. This level of precision guarantees that condensate forms optimally, pulsation dampening is efficient, and integration with your current instrumentation is seamless.

- Quality Assurance Certified by ISO: Shree Vinayak Metals & Tube holds an ISO 9001 certification. This certification is more than a badge; it embodies our strict quality management system, guaranteeing that every product is subjected to rigorous testing and inspection prior to reaching you. We offer test certificates and reports from NABL-approved labs, ensuring you have full assurance of the quality and reliability of our products. The pledge to certified quality is a considerable.

- Expertise and Technical Support: Our team consists of seasoned professionals who possess extensive knowledge of industrial piping and instrumentation. We offer professional advice on choosing the most suitable SS Syphon Tube for your specific application, taking into account factors such as temperature, pressure, medium, and installation method. With the help of our technical support, you can make knowledgeable choices that will optimize your instruments’ efficacy and longevity. This important advisory position provides an operational efficiency.

- Cost-Effectiveness and Long-Term Value: Although we prioritize quality, we aim to provide prices that are competitive. Our SS Syphon Tubes’ enhanced durability and performance result in reduced maintenance needs, fewer replacements, and an extended lifespan for instruments, leading to considerable long-term cost savings – a genuine “Advantage Large” for your finances.

Types of SS Syphon Tubes

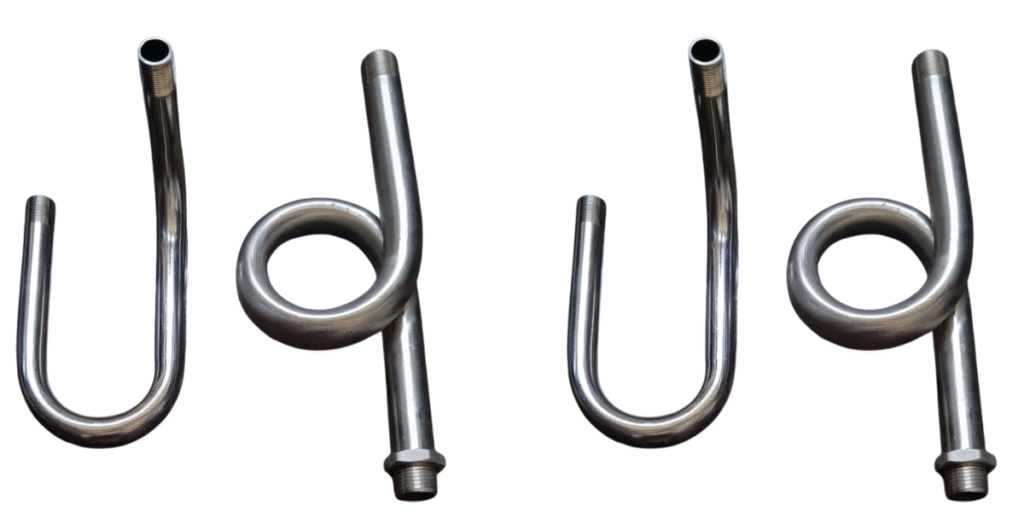

U-Type Syphon Tubes

- Design: Shaped like the letter ‘U’.

- Use: Commonly used in applications involving steam.

- Function: Forms a water seal to protect pressure gauges from direct steam exposure.

- Material Grades: SS 304, SS 316, SS 321.

Q-Type (Pigtail) Syphon Tubes

- Design: Resembles a pig’s tail or spiral loop.

- Use: Ideal for vertical mounting and steam services.

- Function: Allows steam to condense and form a barrier before it reaches the pressure instrument.

- Material Grades: SS 304, SS 316.

Welded Syphon Tubes

- Design: Created by welding stainless steel pipes and fittings.

- Use: Heavy-duty industrial environments with higher pressure and temperature.

- Function: Provides enhanced strength and durability.

- Material Grades: SS 304L, SS 316L.

Threaded Syphon Tubes

- Design: Equipped with threaded ends for easy installation.

- Use: Applications requiring quick assembly and disassembly.

- Function: Connects easily to pressure gauges and piping systems.

- Material Grades: SS 304, SS 316.

Custom Fabricated Syphon Tubes

- Design: Made as per client-specific drawings and specifications.

- Use: Non-standard applications requiring special configurations.

- Function: Custom solutions for unique industrial challenges.

- Material Grades: As per customer requirement.

Conclusion

In the fast-paced industrial environment of Mumbai, the uninterrupted functioning of essential processes depends on the dependability of each component, regardless of its size. Though they are frequently hidden from view, SS Syphon Tubes are essential for safeguarding valuable pressure instrumentation and for maintaining the safety and efficiency of applications involving high temperature and high pressure. We are the best Best SS Syphon Tube Manufacturer.

Among SS Syphon Tube Manufacturers in Mumbai, Shree Vinayak Metals & Tube exemplifies quality and dependability. Our steadfast dedication to manufacturing high-quality, precision-engineered tubes along with our extensive product lineup and customer-focused philosophy positions us as the go-to option for industries in pursuit of excellence.